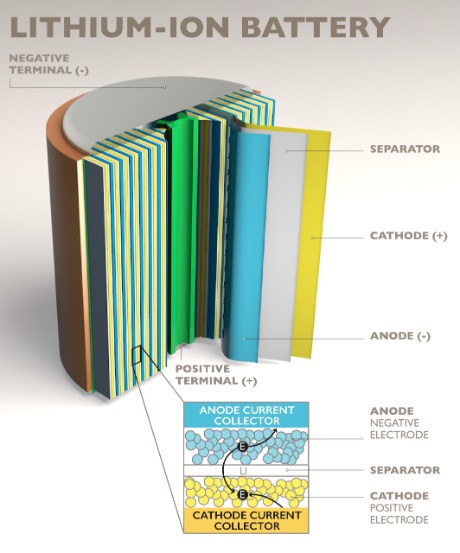

Current collectors serve as the essential backbone of lithium-ion batteries, enabling efficient flow of electrons between electrode materials and external circuits. Typically made from aluminum foil for cathodes and copper foil for anodes, these components directly impact key battery characteristics including energy efficiency, power output, and cycle life.

Despite their fundamental importance, bare metal foils present several challenges: weak adhesion with active materials, high interfacial resistance, and vulnerability to electrochemical corrosion. These limitations can compromise battery performance and longevity.

Advanced carbon coating technologies have emerged as effective solutions to these issues. At LINTEC, we specialize in developing high-performance conductive binders and ready-to-use slurries for carbon-coated aluminum and copper foils.

Our products enhance current collector functionality by:

Creating strong bonds between metal substrates and active materials

Significantly reducing interfacial resistance

Providing excellent corrosion protection under high-voltage operation

Improving mechanical stability throughout battery cycling

LINTEC offers both customized binder formulations and pre-mixed slurries, supporting battery manufacturers in achieving higher energy density and more reliable performance.

For current collector solutions that elevate battery performance, trust LINTEC's expertise in advanced coating technologies—helping power the future of energy storage.